A woven valley shingle installation has other drawbacks including that they are slow to install especially in cold weather and more difficult to repair than the other types.

Roof valley installation instructions.

Then install a non corrosive metal valley flashing of 24 minimum width.

Many roofers cut the shingles across because they say it s safer.

Lap successive sheets of metal flashing a minimum of 12 inches and seal laps.

This video demonstrates the proper installation technique for installing roofing valleys.

The open woven and closed cut methods are demonstrated.

Install the roofing screws vertically along each rib in the panel.

3 important notice this manual serves as a guide to proper installation of the 5v crimp panel.

Before installing a metal roof.

No one of this affirmat.

Roof application panel installation should begin at the gable end of the roof opposite the prevailing rain bearing wind this will provide added assurance against wind driven rain being forced under the laps.

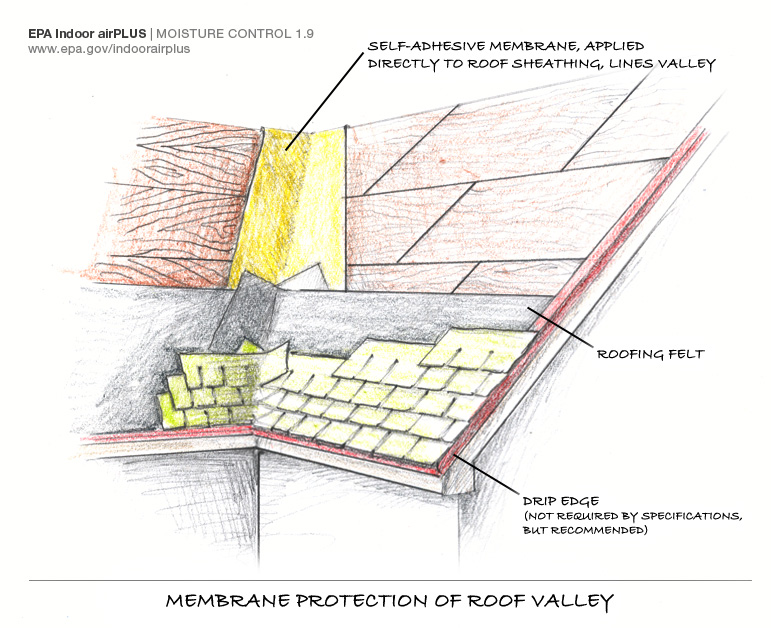

Install an underlayment centered in the roof valley.

Recommended procedures of basic valley flashing installation.

Be sure the larger edge is laid so that the small edge of the next panel will overlap it.

If you have any questions regarding the proper installation of the 5v crimp panel please contact your mid florida metal roofing supply.

Consult our representative for recommendations for your particular roof pitch and about roofing options if you have less than a 3 12 pitch.

In this video i show you how i do the valleys on a shingle roof.